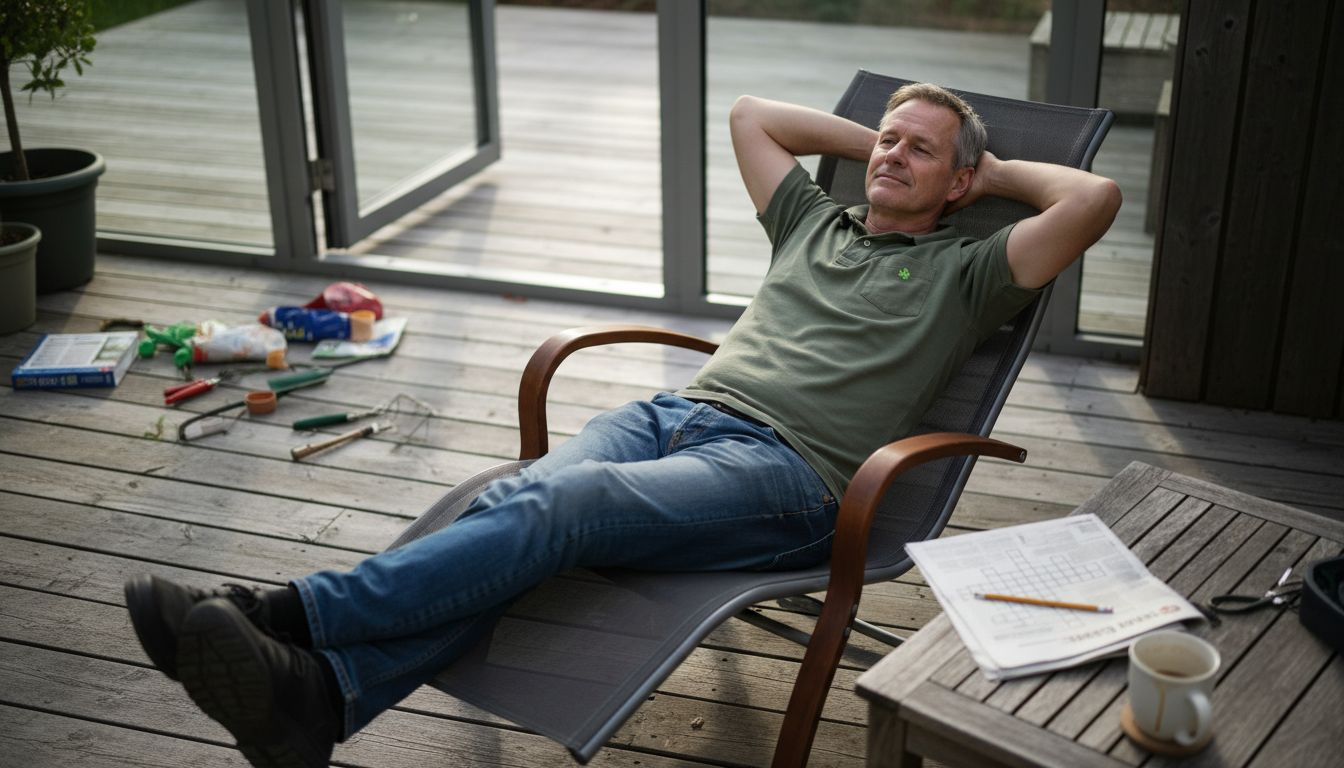

Every American outdoor enthusiast wants gear that is reliable and safe, yet nearly half of preventable equipment injuries are linked to overlooked maintenance steps. Whether you are heading to a summer concert or planning a day at the park, well-cared-for portable seating is essential for your comfort and peace of mind. This guide uncovers practical steps that protect your investment and support the safety of every outing.

Table of Contents

- Step 1: Prepare Your Portable Seating For Inspection

- Step 2: Clean Surfaces And Remove Outdoor Debris

- Step 3: Check Structural Components For Wear And Tear

- Step 4: Lubricate Joints And Folding Mechanisms

- Step 5: Verify Stability And Reassemble For Use

Quick Summary

| Key Takeaway | Explanation |

|---|---|

| 1. Thoroughly Inspect Seating for Safety | Conduct a detailed visual and structural examination to identify any wear or damage that could compromise safety during use. |

| 2. Regular Cleaning Essential for Longevity | Clean portable seating regularly with appropriate materials to prevent decay, prolonging its usability and aesthetic appeal. |

| 3. Lubricate Moving Parts | Apply a silicone or Teflon-based lubricant to joints and mechanisms to ensure smooth operation and prevent wear and rust. |

| 4. Track Maintenance Activities | Keep a maintenance log to note any changes or issues discovered during inspections, allowing for proactive problem resolution. |

| 5. Ensure Stability Before Use | Test seating stability by checking joints and applying weight, simulating actual usage to ensure safe conditions during outdoor activities. |

Step 1: Prepare Your Portable Seating for Inspection

Getting your portable seating ready for a professional inspection requires strategic planning and careful attention to detail. This process helps identify potential safety issues and ensures your outdoor equipment remains in top condition.

Start by thoroughly cleaning your portable chairs or seating system. Remove any dirt, debris, or accumulated grime that might obscure potential damage or wear. Use a soft cloth or specialized outdoor equipment cleaner to wipe down surfaces carefully. Pay extra attention to joints, hinges, and connection points where structural stress can occur. Regular professional inspections help identify potential safety hazards before they become serious problems.

Next, conduct a visual inspection of your portable seating. Check for signs of wear such as fraying fabric, rust on metal components, cracked plastic, or weakened support structures. Look closely at folding mechanisms to ensure they operate smoothly and lock securely. Run your hands along seams and stress points to detect any subtle changes in material integrity. Liability assessments can help facility managers understand potential risks, but your proactive examination is the first line of defense.

Pro tip: Take clear, well-lit photographs of any areas of concern during your inspection. These images can provide valuable documentation for professional assessment and help track changes in your portable seating over time.

Step 2: Clean Surfaces and Remove Outdoor Debris

Cleaning your portable seating and removing outdoor debris is a critical maintenance step that protects your equipment and extends its usable life. This process helps prevent long-term damage and keeps your seating looking great for future adventures.

Begin by gathering the right cleaning supplies tailored to your seating material. Appropriate cleaning products designed for outdoor furniture can make a significant difference in maintaining its condition. For fabric surfaces, use a soft brush to gently remove loose dirt and debris. Mix a mild soap solution with warm water and use a soft cloth to wipe down surfaces thoroughly. Pay special attention to crevices and joints where dirt tends to accumulate. For metal or plastic components, use a microfiber cloth to prevent scratching and ensure a streak-free finish.

After initial cleaning, rinse your portable seating with clean water to remove any soap residue. Preventing dirt and debris accumulation is essential for long-term preservation. Allow the seating to air dry completely in a well-ventilated area, avoiding direct sunlight that might cause material stress or fading. If possible, set up your seating on a clean surface to avoid picking up additional dirt during the drying process.

Pro tip: Keep a dedicated outdoor cleaning kit with microfiber cloths, mild soap, and a soft brush in your storage area. This preparation will make routine maintenance quick and easy whenever you need to clean your portable seating.

Here’s a summary comparing common portable seating materials and their maintenance needs:

| Material Type | Key Maintenance Concern | Typical Cleaning Method |

|---|---|---|

| Fabric/Canvas | Prone to fraying, stains | Mild soap and soft brush |

| Metal | Rust and corrosion risks | Microfiber cloth and lubricant |

| Plastic | Cracks and UV fading | Mild soap and water |

| Composite | Warping and color loss | Gentle wipe and air dry |

Step 3: Check Structural Components for Wear and Tear

Identifying potential structural weaknesses in your portable seating is crucial for ensuring safety and preventing unexpected failures during use. This comprehensive inspection will help you catch small issues before they become significant problems that compromise your equipment’s reliability.

Periodic inspection and tightening of bolts form the foundation of a thorough structural assessment. Begin by carefully examining all connection points metal joints, and fastening mechanisms. Look for signs of rust, corrosion, or metal fatigue. Gently wiggle each joint to check for unexpected movement or looseness that might indicate structural weakness. Pay special attention to welded areas and stress points where different materials connect. Use a flashlight to illuminate hard-to-see areas and inspect for hairline cracks or subtle deformations that could compromise the seating’s integrity.

Next, systematically check the frame and support structures. Liability assessments conducted by professional seating experts recommend a methodical approach to evaluating structural components. Examine folding mechanisms for smooth operation and secure locking. Test the tension of support straps or bands, ensuring they provide consistent support without fraying or stretching. For fabric or canvas seating, look for signs of material fatigue such as thinning, discoloration, or areas where the material appears stretched or weakened. Gently press on key structural points to assess their rigidity and overall condition.

Pro tip: Keep a small notebook or digital log to track your inspections, noting any changes or potential issues you discover during each check. This documentation can help you identify developing problems before they become serious safety concerns.

Step 4: Lubricate Joints and Folding Mechanisms

Lubricating the joints and folding mechanisms of your portable seating is a critical maintenance step that ensures smooth operation and prevents premature wear. This process helps keep your equipment functioning smoothly and extends its overall lifespan.

Regular maintenance of folding mechanisms requires careful selection of the right lubricant and application technique. Start by choosing a silicone or Teflon based lubricant specifically designed for outdoor equipment. Clean all joints thoroughly with a soft cloth to remove any existing dirt or debris before applying the lubricant. Focus on pivot points, hinges, and sliding mechanisms where metal components interact. Apply a thin layer of lubricant sparingly but thoroughly work it into all moving parts. Be careful not to over lubricate which can attract additional dirt and potentially damage the mechanism.

Applying appropriate lubricants to joints and moving parts prevents rust and ensures ease of use. After initial lubrication test each folding mechanism by carefully opening and closing it multiple times. This helps distribute the lubricant evenly and allows you to identify any areas that might need additional attention. Pay special attention to any areas that feel stiff or resistant during movement. If you encounter significant resistance or notice unusual sounds during operation, it might indicate more significant structural issues that require professional inspection.

Pro tip: Keep a clean microfiber cloth and your chosen lubricant in a sealed plastic bag in your outdoor gear kit. This preparation allows you to perform quick maintenance checks and lubrication whenever you notice potential issues during your adventures.

Step 5: Verify Stability and Reassemble for Use

The final stage of portable seating maintenance involves carefully verifying its overall stability and preparing it for safe use. This critical step ensures that all your previous maintenance efforts translate into a reliable and secure seating solution for your outdoor adventures.

Ensuring the stability of portable seating through regular inspections requires a systematic and thorough approach. Begin by laying out all components on a flat surface and double checking that each piece is clean and properly prepared. Test each joint and connection point by gently applying pressure from multiple angles. Watch for any unexpected movement or wobbling that might indicate structural weakness. Confirm that all locking mechanisms engage fully and hold firmly when the seating is in its deployed position. Pay special attention to weight distribution points and areas that will bear the most stress during actual use.

Professional inspection services recommend carefully verifying seating stability before considering the maintenance process complete. Perform a series of controlled tests by gradually applying weight to different areas of the seating. Simulate typical usage scenarios to ensure consistent performance. If you notice any hesitation in the structure or hear unusual sounds during testing stop immediately and reassess the components. Remember that even minor instabilities can compromise user safety and potentially lead to equipment failure during critical moments.

Pro tip: Create a simple visual checklist that you can quickly reference after each maintenance session. This quick reference guide will help you consistently perform thorough stability checks and catch potential issues before they become serious problems.

This reference table outlines inspection and maintenance frequency recommendations:

| Task | Suggested Frequency | Primary Benefit |

|---|---|---|

| Visual inspection | Monthly | Early issue detection |

| Deep cleaning | Every 2-3 months | Prolonged equipment life |

| Lubricating joints | Every 6 months | Smoother operation |

| Tightening bolts | Before heavy use | Prevents structural failures |

Elevate Your Outdoor Comfort with Durable Portable Seating Solutions

Maintaining portable seating for lasting outdoor comfort takes more than just regular cleaning and inspection. The article highlights key challenges like identifying wear and tear, lubricating folding mechanisms, and ensuring stability to prevent equipment failure. If you want to avoid inconvenient breakdowns or safety risks while enjoying your outdoor adventures, switching to high-quality, durable seating designed for effortless maintenance is essential.

Experience the perfect blend of lightweight design, durability, and user comfort with Sitpack’s innovative lineup of seats. Our collection, including the Campster II and Sitpack Zen, offers foldable chairs engineered for long-lasting performance without the frequent upkeep hassles. Explore Sitpack’s portable seating solutions and discover accessories that enhance your outdoor experience such as seat warmers and thermal blankets.

Don’t wait until your current seating shows signs of wear or instability. Take control now and upgrade to seating that supports your active lifestyle with peace of mind. Shop today at Sitpack for reliable, easy-to-maintain outdoor seating that travels as well as you do.

Frequently Asked Questions

How can I prepare my portable seating for inspection?

To prepare your portable seating for inspection, start by thoroughly cleaning the surfaces to remove dirt and grime. Conduct a visual inspection to look for signs of wear, such as fraying fabric or rust, and take clear photographs of any areas of concern for documentation.

What is the best way to clean my portable seating?

The best way to clean your portable seating is to use a mild soap solution with warm water and a soft cloth. Make sure to focus on crevices and joints, then rinse with clean water and let the seating air dry completely to avoid damage.

How often should I check the structural components of my portable seating?

You should check the structural components of your portable seating at least once a month. This includes tightening bolts, inspecting joints for rust or fatigue, and ensuring that folding mechanisms operate smoothly without resistance.

What type of lubricant should I use for joints and folding mechanisms?

Use a silicone or Teflon-based lubricant specifically designed for outdoor equipment on the joints and folding mechanisms of your portable seating. Apply a thin layer to all moving parts to prevent rust and ensure smooth operation, then check the mechanisms regularly for any stiffness.

How can I verify the stability of my portable seating?

To verify the stability of your portable seating, lay all components out on a flat surface and apply gentle pressure at various points to check for unexpected movement. Always ensure that locking mechanisms engage fully and perform controlled tests by gradually applying weight to simulate normal use.

What maintenance tasks should I prioritize for my portable seating?

Prioritize conducting a visual inspection monthly, deep cleaning every 2-3 months, and lubricating joints every 6 months. Additionally, make sure to tighten bolts before heavy use to prevent structural failures and maintain safety during outdoor activities.

Recommended

- What Is a Camp Stool? Complete Outdoor Guide – Sitpack

- What Is a Camp Stool? Complete Outdoor Guide – Sitpack

- What Is a Camp Stool? Complete Outdoor Guide – Sitpack

- What Is a Camp Stool? Complete Outdoor Guide – Sitpack

- 7 Essential Steps for a Summer Lawn Care Checklist in Minnetonka – YardWoo Lawncare